Uit liefde voor materiaal

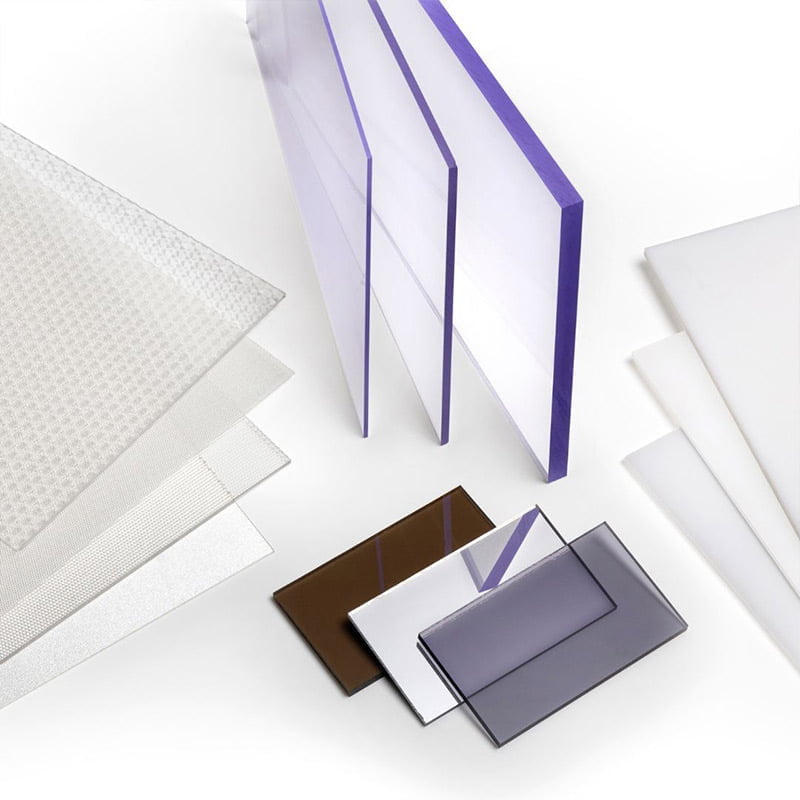

Welkom in onze wereld van kleur, licht, vorm en verbeelding. Als toonaangevend specialist in duurzaam (design)kunststof delen we graag onze liefde voor materiaal met jou. Kom inspiratie opdoen, ideeën realiseren, mooie projecten ontwikkelen. Hier vind je alle materiaal en kennis die je nodig hebt.

Laat je inspireren

Materiaal is een onuitputtelijke bron van kleur, licht, vorm en toepassing. Ontdek de mogelijkheden.

Vind voor jouw project het perfecte materiaal

Uit liefde voor materiaal

Dat één plaat kunststofmateriaal de bron kan zijn van oneindig veel nieuwe werelden en creaties: daar gaat ons hart sneller van kloppen. Die liefde voor het materiaal en de onbeperkte mogelijkheden ervan delen we graag met je. Omdat wij alles doen uit liefde voor materiaal kun jij rekenen op topkwaliteit en topadvies.

Realiseert dromen en ideeën

We verplaatsen en verdiepen ons dagelijks in de dromen- en ideeënwereld van onze opdrachtgevers. Omdat Pyrasied niet alleen duurzame (design)kunststoffen levert en bewerkt, maar deze ook zelf ontwikkelt én fabriceert kunnen we vrijwel elke wens omzetten in realiteit. Laat jouw fantasie de vrije loop!

Gaat verder waar anderen stoppen

Pyrasied gaat door waar anderen afhaken. Het denken in oplossingen en mogelijkheden zit nu eenmaal diep verankerd in ons DNA. Logisch dat wij je op alle mogelijke manieren willen helpen je doelen te bereiken. Met materialen, inspiratie, advisering, realisering én oprechte professionele betrokkenheid bij jouw project(en).

Co-creëert

Betrek ons gerust bij de ontwikkeling van jouw project. Door onze expertise en jarenlange praktijkervaring helpen we architecten, engineers en interieurbouwers snel verder bij de juiste materiaalkeuze, materiaalbewerkingen én materiaaltoepassingen. Dat we samen met jou een groot succes willen maken van jouw project: reken daar maar op.

Inspireert

Graag inspireren we je met materiaaloplossingen van vandaag en morgen. Bijvoorbeeld door met jou bijzondere projecten te delen. Maar ook door kunststofmaterialen speciaal voor én met jou te ontwikkelen. Dat we je hoe dan ook willen blijven prikkelen als het gaat om materiaalinnovaties: daar kun je van op aan.

Biedt de meeste keuze

Bij Pyrasied kun je sinds 1984 kiezen uit een gigantische voorraad uiteenlopende soorten (gerecycled) acrylaat, milieuvriendelijke kunststoffen, PETG, polycarbonaat en design kunststoffen. Door onze uitgebreide ervaring met zowel kunststofmateriaal als met alle mogelijke bewerkingen en toepassingen ervan bieden we jou de meeste keuze en opties.

Garandeert gezonde marges

Pyrasied vertegenwoordigt een groot aantal Nederlandse en buitenlandse topmerken kunststofmaterialen. Omdat we als een van de grootste Europese kunststofexperts de omloopsnelheid in onze voorraden kunststofmaterialen hoog houden, hanteren we scherpe verkoopprijzen. Hierdoor ben jij verzekerd van gezonde marges.

De 7 zekerheden van Pyrasied:

Uit liefde voor materiaal

Dat één plaat kunststofmateriaal de bron kan zijn van oneindig veel nieuwe werelden en creaties: daar gaat ons hart sneller van kloppen. Die liefde voor het materiaal en de onbeperkte mogelijkheden ervan delen we graag met je. Omdat wij alles doen uit liefde voor materiaal kun jij rekenen op topkwaliteit en topadvies.

Realiseert dromen en ideeën

We verplaatsen en verdiepen ons dagelijks in de dromen- en ideeënwereld van onze opdrachtgevers. Omdat Pyrasied niet alleen duurzame (design)kunststoffen levert en bewerkt, maar deze ook zelf ontwikkelt én fabriceert kunnen we vrijwel elke wens omzetten in realiteit. Laat jouw fantasie de vrije loop!

Gaat verder waar anderen stoppen

Pyrasied gaat door waar anderen afhaken. Het denken in oplossingen en mogelijkheden zit nu eenmaal diep verankerd in ons DNA. Logisch dat wij je op alle mogelijke manieren willen helpen je doelen te bereiken. Met materialen, inspiratie, advisering, realisering én oprechte professionele betrokkenheid bij jouw project(en).

Co-creëert

Betrek ons gerust bij de ontwikkeling van jouw project. Door onze expertise en jarenlange praktijkervaring helpen we architecten, engineers en interieurbouwers snel verder bij de juiste materiaalkeuze, materiaalbewerkingen én materiaaltoepassingen. Dat we samen met jou een groot succes willen maken van jouw project: reken daar maar op.

Inspireert

Graag inspireren we je met materiaaloplossingen van vandaag en morgen. Bijvoorbeeld door met jou bijzondere projecten te delen. Maar ook door kunststofmaterialen speciaal voor én met jou te ontwikkelen. Dat we je hoe dan ook willen blijven prikkelen als het gaat om materiaalinnovaties: daar kun je van op aan.

Biedt de meeste keuze

Bij Pyrasied kun je sinds 1984 kiezen uit een gigantische voorraad uiteenlopende soorten (gerecycled) acrylaat, milieuvriendelijke kunststoffen, PETG, polycarbonaat en design kunststoffen. Door onze uitgebreide ervaring met zowel kunststofmateriaal als met alle mogelijke bewerkingen en toepassingen ervan bieden we jou de meeste keuze en opties.

Garandeert gezonde marges

Pyrasied vertegenwoordigt een groot aantal Nederlandse en buitenlandse topmerken kunststofmaterialen. Omdat we als een van de grootste Europese kunststofexperts de omloopsnelheid in onze voorraden kunststofmaterialen hoog houden, hanteren we scherpe verkoopprijzen. Hierdoor ben jij verzekerd van gezonde marges.

Neem direct contact op met het Pyrasied team

op je telefoon

Bewaar mijn gegevens

Deze opdrachtgevers delen onze liefde voor materiaal

Van architect tot interieurbouwer en van R&D professional tot designer: ons opdrachtgeversportfolio kent een grote verscheidenheid. En daar zijn we trots op!